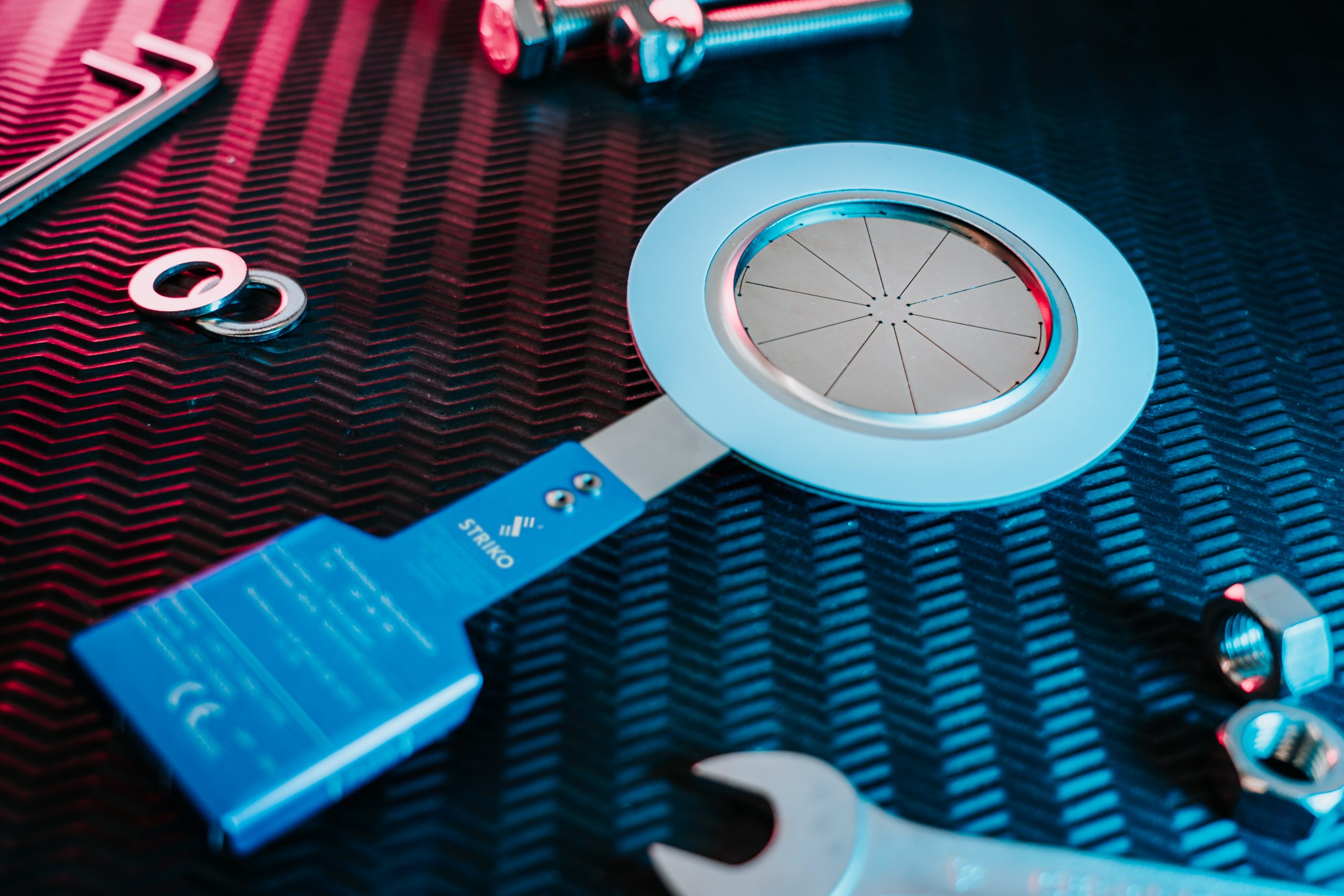

STRIKO tank rupture discs protect tank containers and tank wagons against impermissible overpressure and/or underpressure. The flat tank rupture disc is available in the versions SF-M-TB (vacuum-supported and with PTFE protective film on the product side) and SF-MD-TB (double-acting). STRIKO tank rupture discs are used to transport gases, liquids or multiphase media safely on our roads and tracks. A flanged centering collar allows reliable installation and centering of the rupture disc between two flanges (fail-safe installation). Tank bursting discs for common bursting pressures are available from stock in nominal sizes DN 65 and DN 80, offering you the greatest possible flexibility and rapid availability.

Advantages in the application

- Reliable pressure protection of tank container and tank wagons

- No fragmentation of metallic parts

- Flat design

- SF-M-TB vacuum-proof and with PTFE protective film on product side

- SF-MD-TB as ideal protection against overpressure and underpressure

- Fail-safe function due to centering collar

- Available in special materials such as nickel, Hastelloy®, Inconel® or tantalum

- Nominal sizes DN 65 and DN 80 for common bursting pressures and materials available from stock

- with 3D type plate as standard for reliable identification of the correct installation direction

- suitable for gases, vapors and liquids

- working ratio: up to 90%

- Tolerance: up to +/- 5%

Specifications:

Werkstoffe

Nennweiten

Berstdrücke

Arbeitsverhältnis

Bersttoleranz

Einsatztemperaturbereich

Einbau vor Sicherheitsventil?

Your contact for Rupture Disc for Tank Container

Answering your questions precisely and competently - that is our goal.

Simply get in touch directly with your contacts from the divisions.