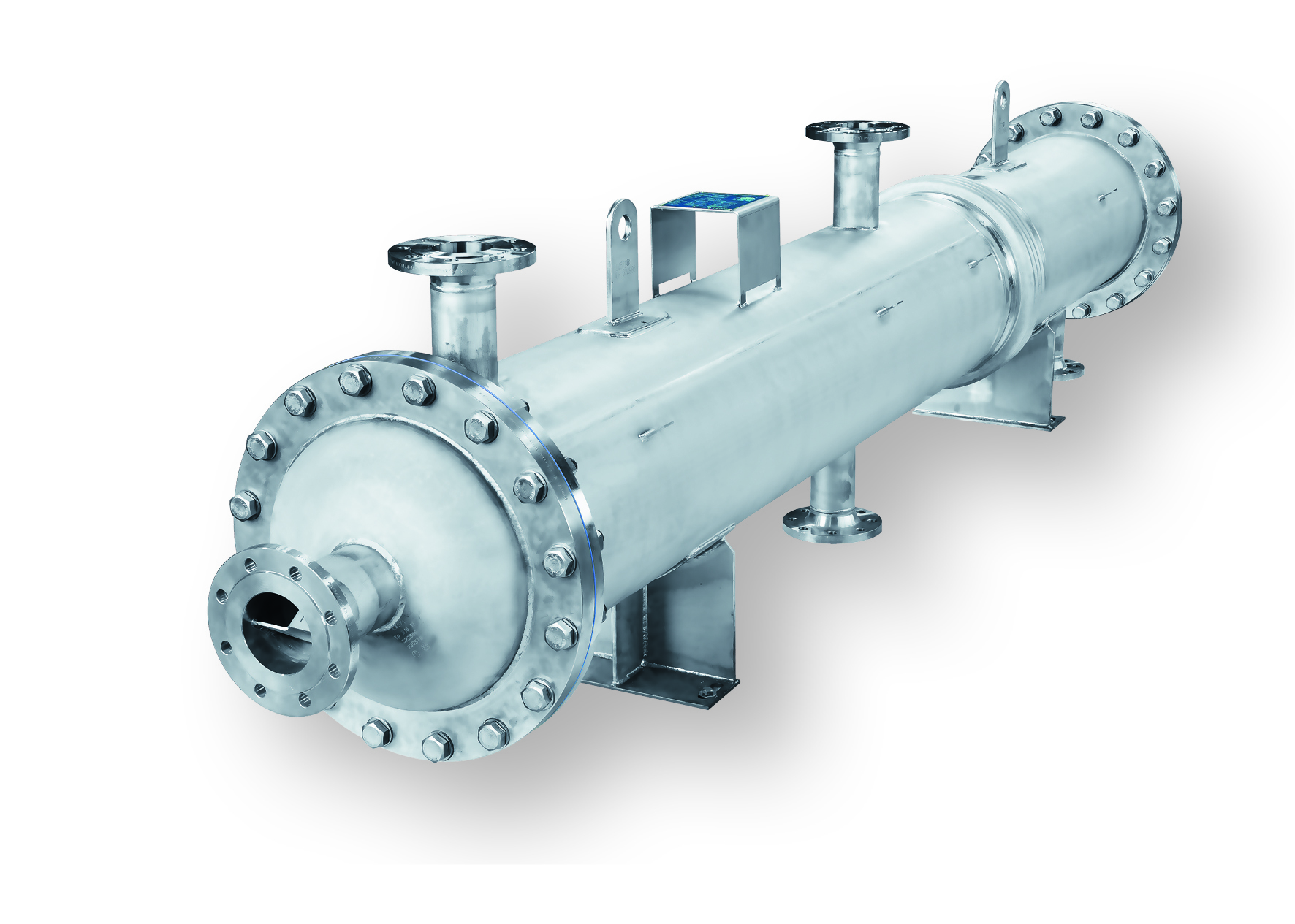

for highly viscous media

STRIKO heat exchangers are especially designed for tempering viscous to highly viscous media – reliably and smoothly up to a range of 500,000 mPas. The applications are thus broadly diversified – the cooling of silicon, bitumen or hexane, the heating of static mixer during chocolate production and the tempering of plastic melts are all part of it.

Service description

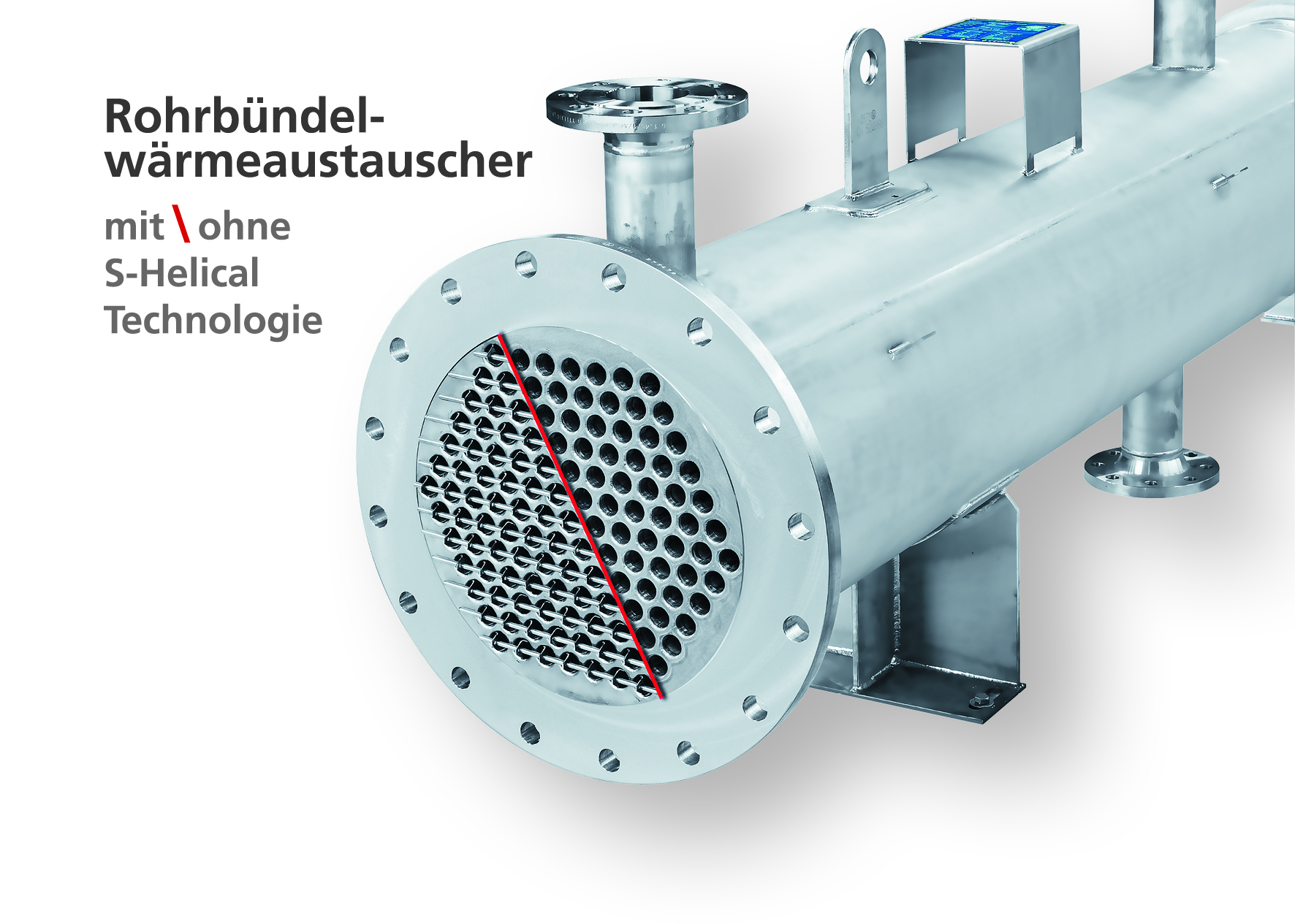

The special feature of the heat exchanger models is the use of helical mixing elements in the product room pipes. This prevents sticking or fouling of product at the pipe interior wall, because their product mass is constantly mixed and turned. This effect also occurred for one-digit reynold numbers. There are different options of integrating the mixing element chains of the Helical type in the product room pipes:

- slide-in, designed as removable – the most widespread solution (e.g. for cleaning, control, revision)

- slide-in, firmly welded to the pipe interior wall

- shrink wrapped (for better heat transfer)

- soldered (for optimum heat transfer, high axial load ability, no gaps)

Design Examples

Advantages in the application

- can be delivered in all standard stainless steels and special materials such as Duplex and Hastelloy®

- nominal widths DN 15 to DN 800 (other dimensions upon request)

- nominal widths DN 15 to DN 800 (other dimensions upon request)

- nominal widths DN 15 to DN 800 (other dimensions upon request)

- optionally shrinking, welding or soldering the mixing elements

- in addition to the design according to DGRL or ASME VIII/Div. 1 and production, STRIKO also assumes all necessary checks

Individual solutions

Your contact for Multi-Tube Heat Exchanger and Tubular Heat Exchanger

Answering your questions precisely and competently - that is our goal.

Simply get in touch directly with your contacts from the divisions.