high performance universal mixer

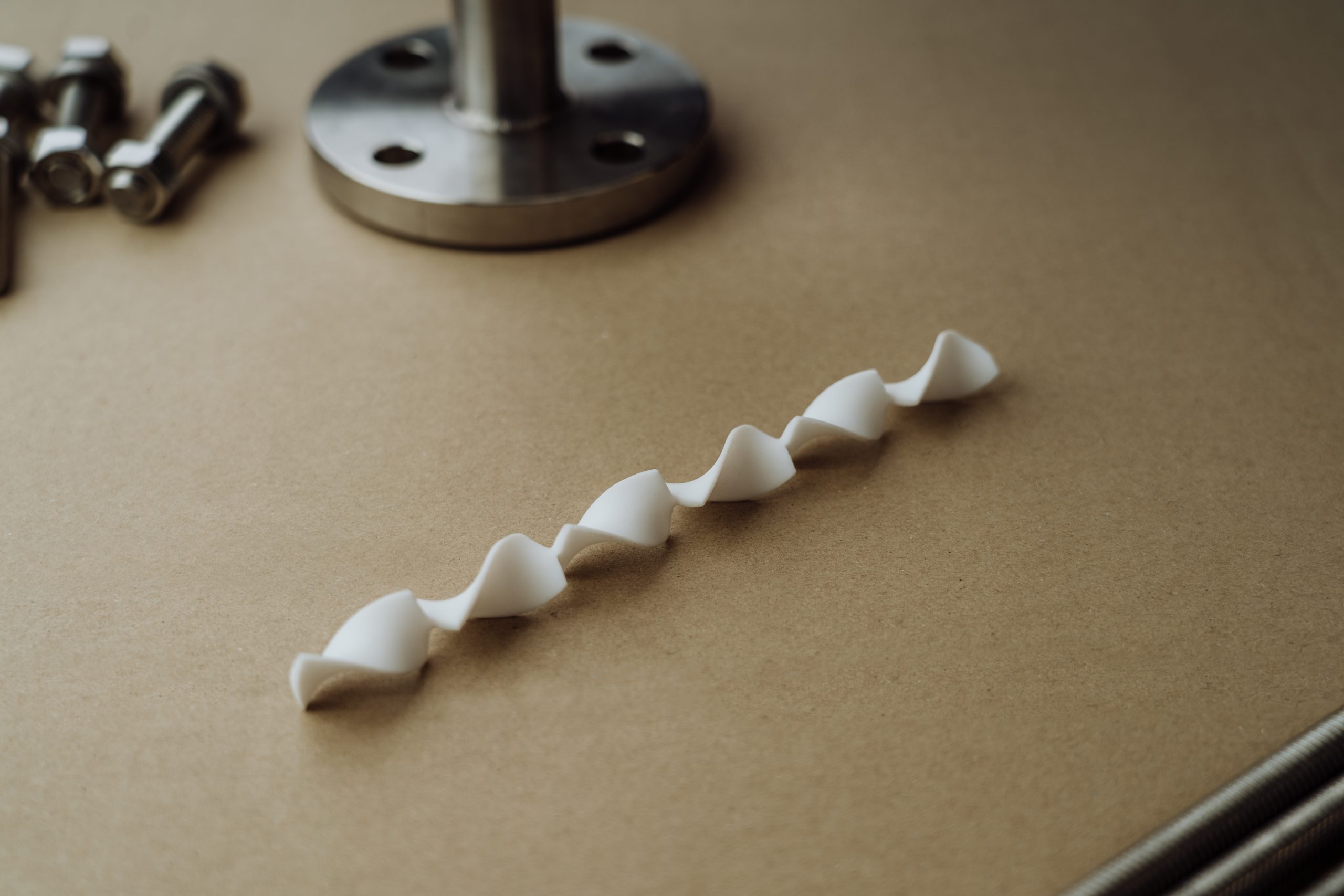

The Helical / K-Helical type mixers are static pipe mixers and ideally suited for the homogenous consolidation of low viscosity, turbulent and laminar flowing media.

The requirements of the process environment and the wishes of our customers decide about the individual design of a system. All stainless steels and standard steels are available for the material, for plastics, e.g. PVC, PE-HD, PP or PVDF, it is also coated with fibre reinforced. The housing can be manufactured from glass or PTFE coated pipes as well.

Description of services

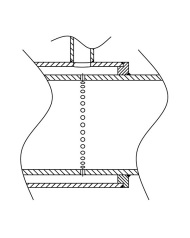

The Helical / K-Helical mixing elements are perfectly suited for the homogeneous mixing of turbulent and laminar flowing media. Careful design of the static mixer is important for all applications. This is why this is done in close consultation with our customers - and always customised for the respective application. The mixing element chains consist of axially twisted elements arranged in opposite directions. This divides the volume flow highly efficiently - the division increases depending on the number of elements used. The potentiation and thus a high mixing quality is achieved not only with turbulent flow, which occurs at low viscosities and high flow velocities, but also with laminar flow. The length of the mixing element chain depends on the application, the space available and other boundary conditions such as pressure loss and the desired mixing quality. Due to the innovative design and in-house production at STRIKO, numerous materials can be used. Mixing elements of the Helical type are manufactured up to DN 125, larger nominal diameters are fitted with elements of the K-Helical type.

Typical applications

- sterile applications (use of soldered mixing elements)

- insulin manufacture

- foods industry: homogenising of mayonnaise

- plastics processing in combination with heat exchanger for homogenising and tempering the mixing product before the injection moulding

- mixing of liquids such as paints

- mixing of gasses into liquids, e.g. for iron precipitation

- can be combined with other mixer types for other applications

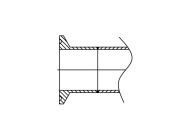

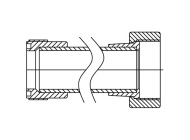

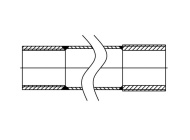

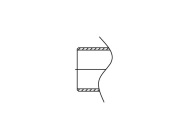

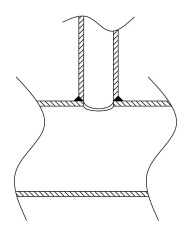

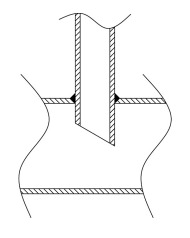

Connection types

Your contact for Helical – Universalmixer

Answering your questions precisely and competently - that is our goal.

Simply get in touch directly with your contacts from the divisions.