Advantages

- high thermal shock resistance

- Excellent thermal conductivity

- High mechanical pressure resistance

- Operating temperatures from max. 180 °C to 200 °C, with PTFE impregnation up to 230 °C

We do this

- fast: Especially in the area of plant safety, agile crisis management is of high importance - we do it: quickly and thoroughly!

safely: Whether in the process, in planning or in the budget: Our products provide you with safety. This means protection for your personnel, the environment and your machines, and thus stability in your process and quality for your products.

individually: The optimal solution for you is always our priority. That's why we analyze every case down to the smallest detail, gladly also directly on site. This is the only way to create customized products that are exactly right for your application.

Our assortment

FAQ

For which applications are graphite block heat exchangers used?

These heat exchangers are used for aggressive media, because graphite has very high chemical resistance.

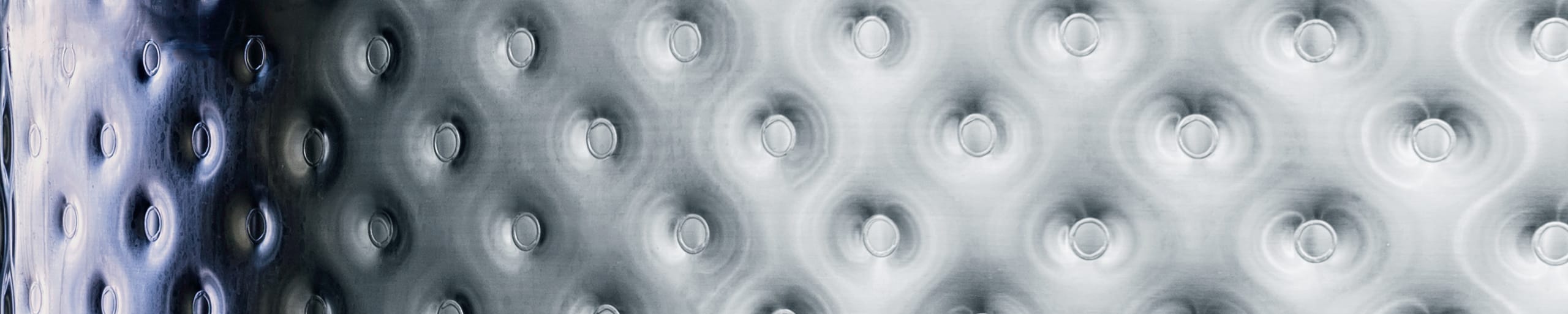

What designs and materials are available?

The thermal plates are available in two versions: as a simplex or duplex cushion profile. These options are delivered in almost every shape and size made of stainless steel, nickel and special alloys such as Hastelloy or titanium.

For what kind of applications are thermoshelves suitable?

The thermal plates are available in two versions: as a simplex or duplex cushion profile. These options are delivered in almost every shape and size made of stainless steel, nickel and special alloys such as Hastelloy or titanium.

What can thermal plates be used for?

- Immersion in liquid applications

- Coating of containers

- Thermal plates as containers

Can heat exchangers with mixing elements be used everywhere?

Basically, yes. However, this investment makes sense only for applications used for tempering of viscous media, for which plate heat exchangers, etc. are not suitable. Whether pharmaceutical, chemical or food industry – the design (removable or fixed integrated mixing elements) is always configured depending on the application.

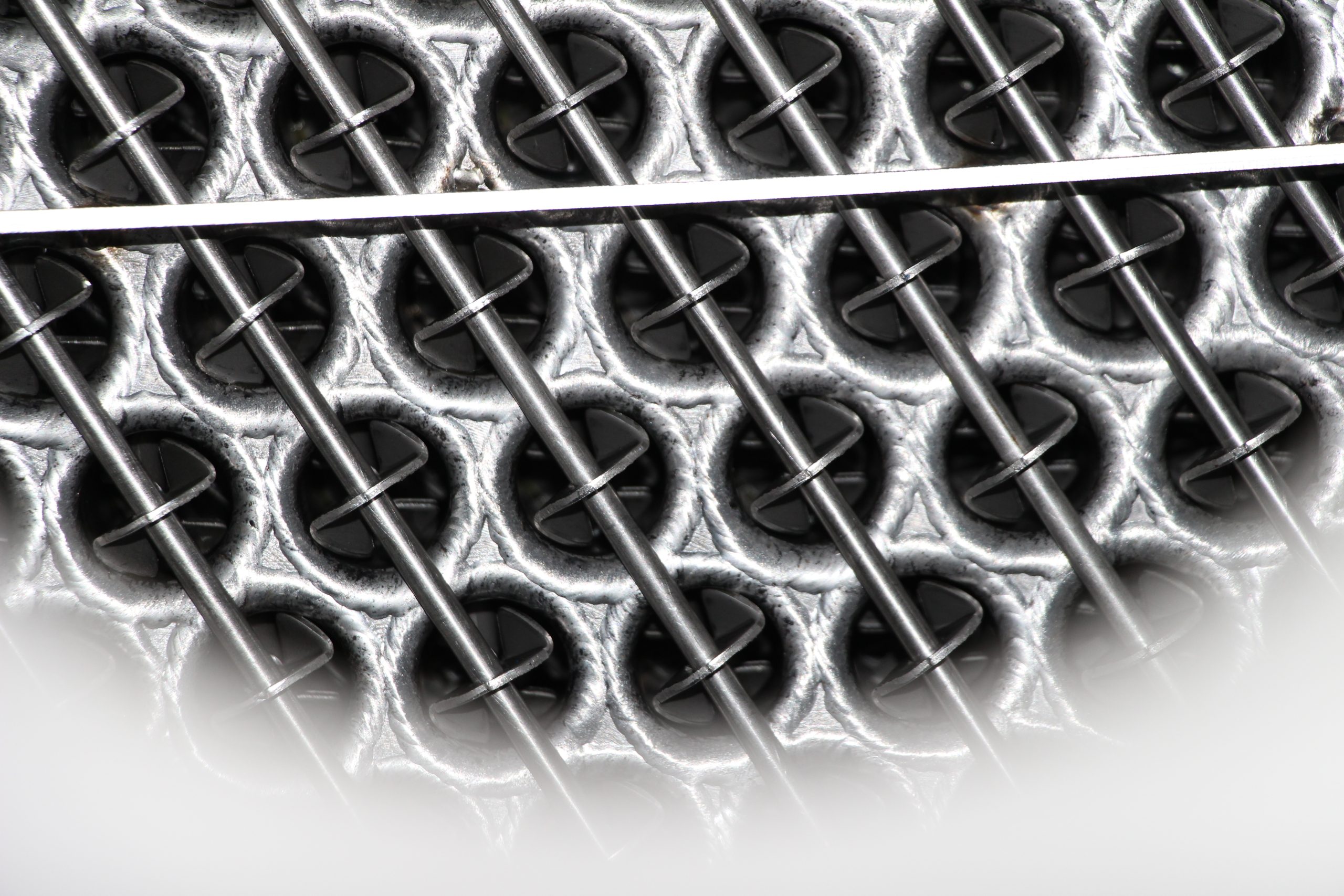

Why are heat exchangers for viscous media equipped with mixing elements?

During tempering of viscous media, the product area tubes tend to cake. To minimize and prevent the so-called fouling and to improve the heat transfer, mixing elements are used.

Thus, the product which flows laminar is continuously shifted from the centre of the pipe to the pipe wall and vice versa. As a consequence, the time intervals between downtimes for cleaning the the product area tubes and the construction size / length of the heat exchanger can be reduced as compared with the heat exchangers with no mixing elements.