Rupture Disc equipment with integrated alarms can be of diverse design. Either an inductive proximity switch is used that works in combination with other metal flags on the burst membrane, or the conductor path to be destroyed is directly integrated in the Rupture Disc, so that the amount of components can be further reduced. Special solutions such as extruder bursting discs with integrated breakage monitoring round off the STRIKO offer.

Alarm triggering by means of inductive proximity switches

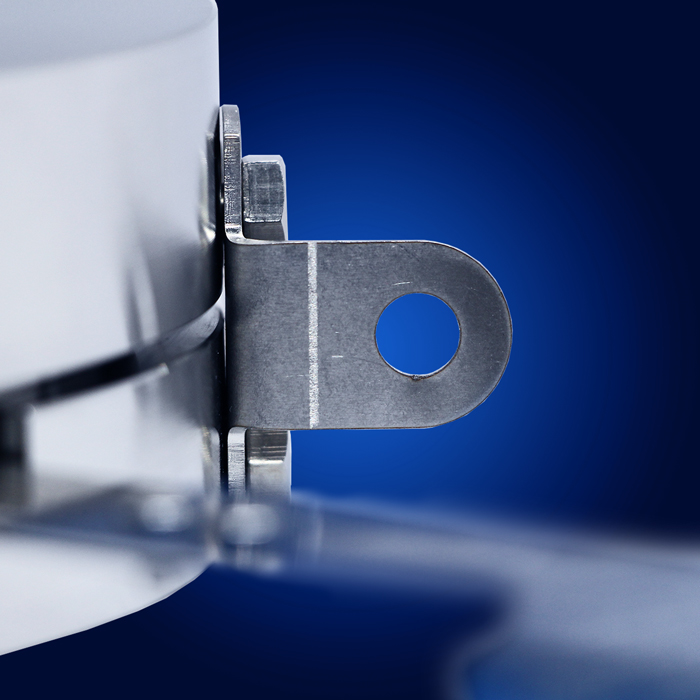

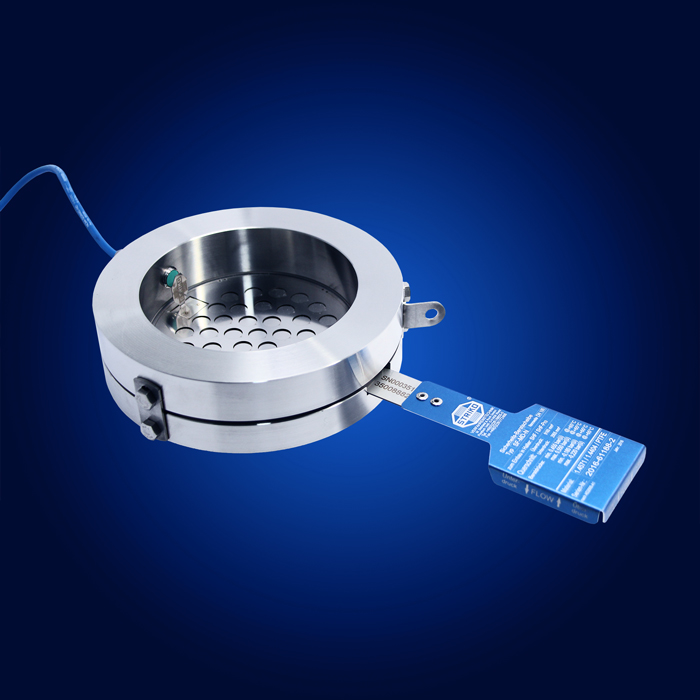

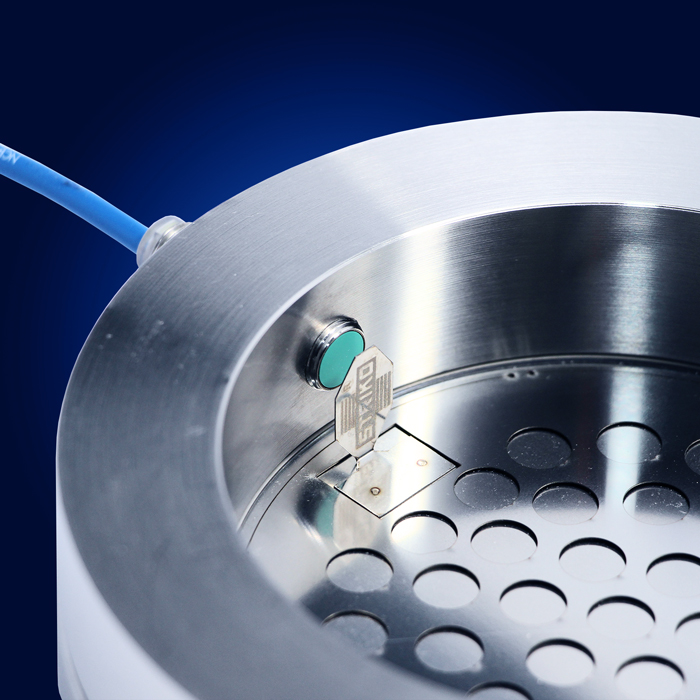

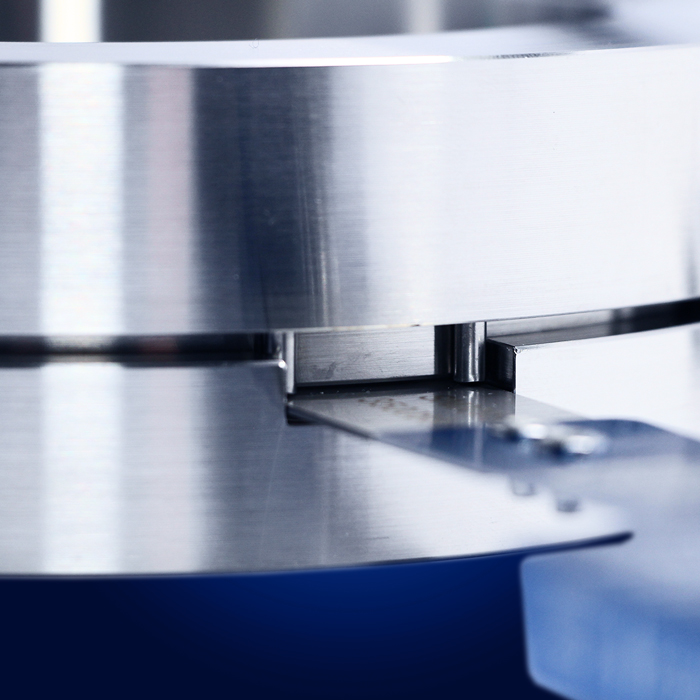

With the help of inductive proximity switches the response of Rupture Disc can be economically and permanently monitored. For this purpose, the bursting disc holder is furnished with an inductive proximity switch which is opened by a metal flag attached to the burst membrane of the Rupture Disc. Once the Rupture Disc responds conventionally, the burst membrane turns together with the signal flag. Thus the bursting disc’s cross-sectional area will be opened as desired. At the same time, the opening of the Rupture Discis detected and the necessary measures may be taken.

By subsequently replacing the bursting disc the original status is restored; the signal flag mounted on the brand new bursting disc in front of the proximity switch safeguards the switch again and will keep it closed until the bursting disc device will respond anew. Choosing this solution means to invest only once in a bursting disc holder along with an inductive proximity switch. No additional costs will incur thereafter – except the usual ones for the replacement of the bursting disc. Consequently, spares and assembly costs will everlastingly decrease. On the contrary, when deciding in favour of the conventional solution with a bursting disc and a connected, separate burst indicator of the series SVT-02, not only the bursting disc but also the additional burst indicator must be replaced.

Advantages in the application

- Quick identification of a malfunction

- Simple assembly

- Maintenance-free

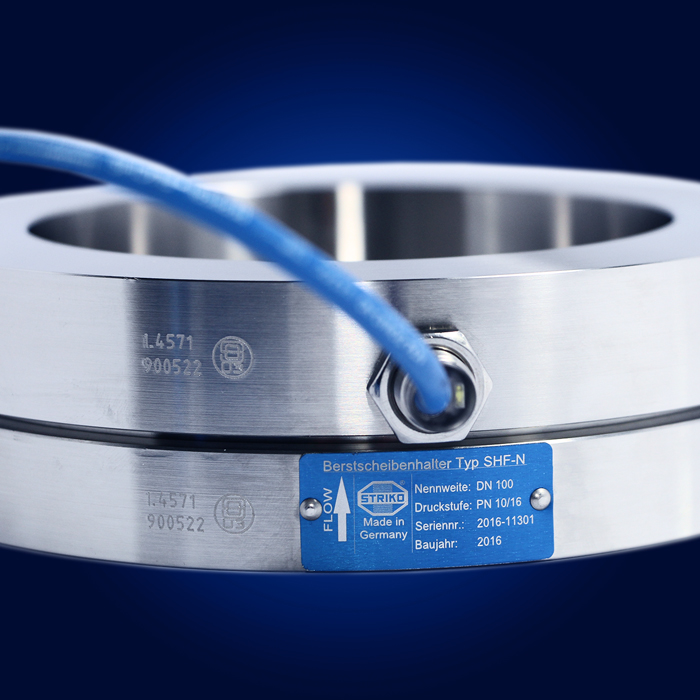

- Can be used in STRIKO standard bursting disc holders SHF and SHU

- Deliverable in nominal widths DN 25 to DN 400

- In every system it can be combined with STRIKO metal burst safety devices

- Continuous temperature range from -25° to +100°

- Design with inductive proximity switch

Specifications:

Switch element function

Rated voltage Uo

Reverse polarity and short circuit protected

Switch status display

Ambient temperature

Connecting cable

Enclosure material

Protection category

NAMUR EN 60947-5-6:2000 / IEC 60947-5-2:2007

Electro-magnetic compatibility

ATEX certificate

Note on ATEX:

Your contact for Rupture Disc Equipment with integrated alarm / special solutions

Answering your questions precisely and competently - that is our goal.

Simply get in touch directly with your contacts from the divisions.