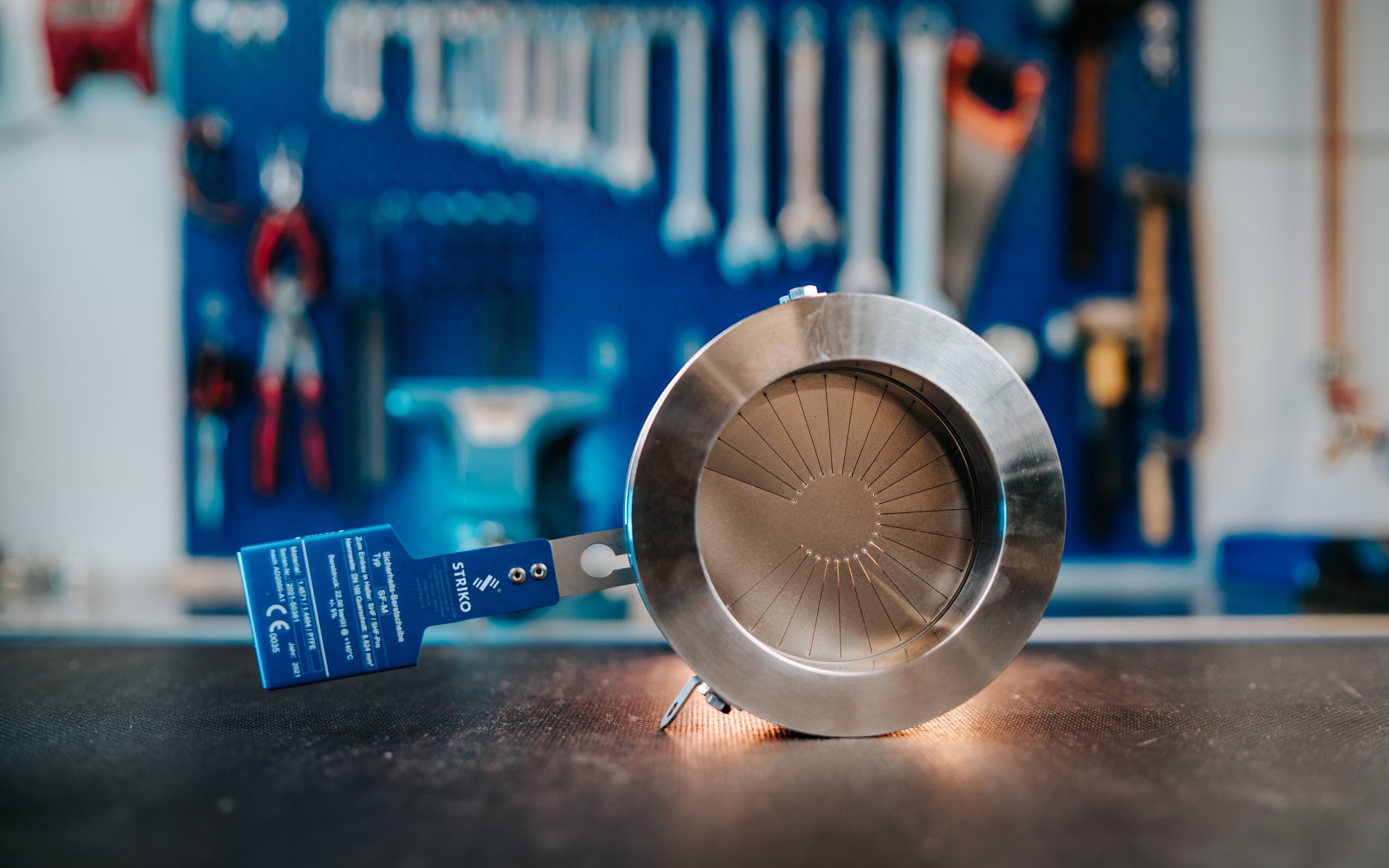

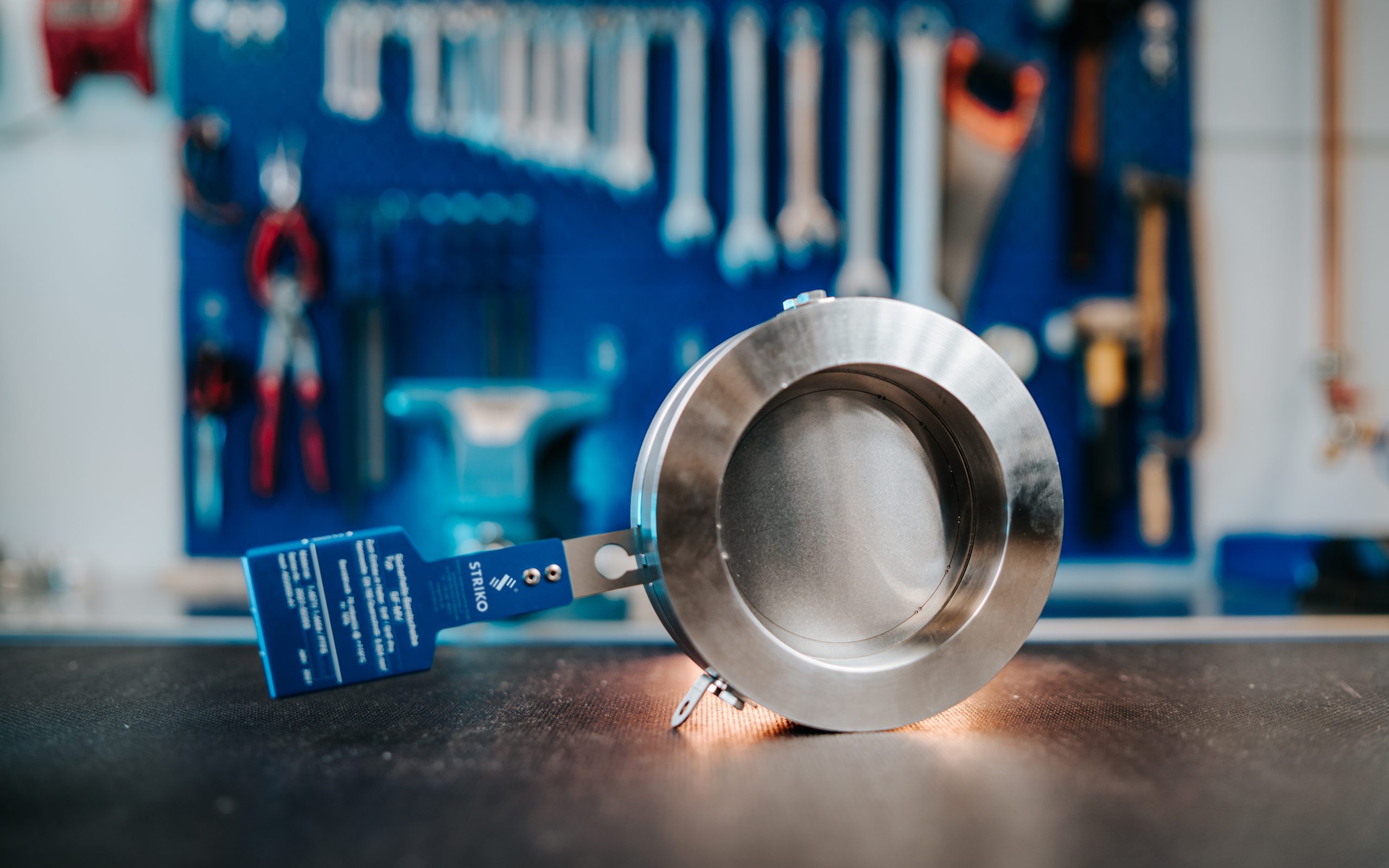

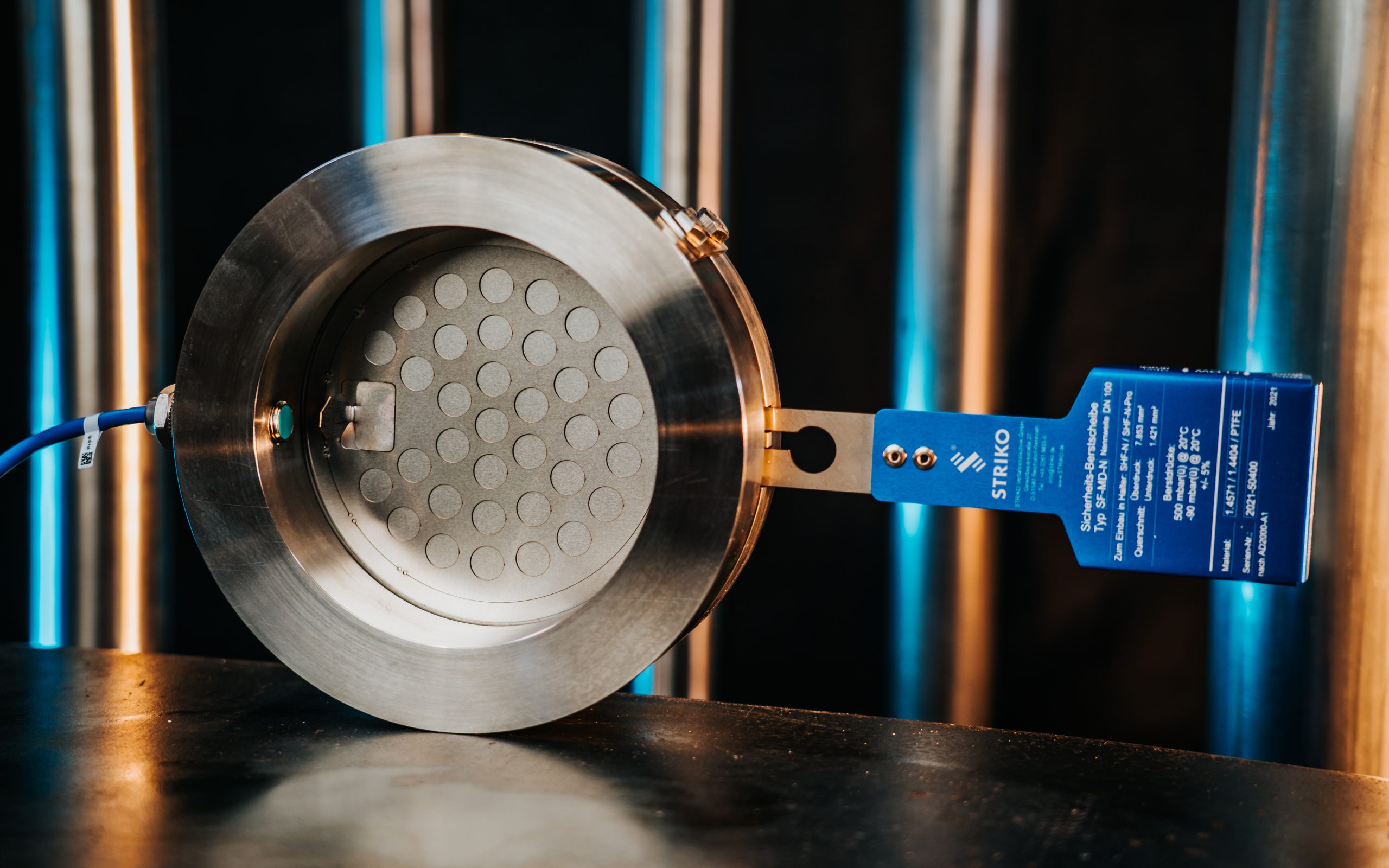

Flat metal rupture disc for direct installation between flanges – without holder also for retrofitting in your existing systems. The multi-part (created by several positions) rupture disc are used to secure mainly low and static overpressure and/or underpressure.

Models

- SF-MSTRIKO – Flat, Multilayered

- SF-MVSTRIKO – Flat, Multilayered, Vacuum Supported

- SF-MDSTRIKO – Flat, Multilayered, Double Acting (different pressures in over/under pressure direction)

Advantages in the application

- used with or without holder

- can be delivered with different burst pressures in overpressure and underpressure direction

- upon request vacuum resistant with integrated vacuum support

- insensitive design with simple handling

- working ratio: 80% by use of special materials

- torque insensitive

- equipped with a 3D name-plate for safe detection of correct direction of installation as a standard

- suitable for gasses, vapours and liquids

Specifications:

Werkstoffe

Stainless steels, nickel, tantal, inconel, hastelloy,…

Nennweiten

DN 15 – DN 600, other sizes on request

Berstdrücke

from 0.025 bar (g) to appr. 30 bar (g)

Arbeitsverhältnis

80 %

Bersttoleranz

min. +/- 5 %

Einsatztemperaturbereich

-120 ℃ to +260 ℃ (PFA), +480°C (metallic)

Berstscheibenhalter

SHF and SHF Pro

Vakuumstütze

optional

Alarmgeber

optionally installed on discharge side

Einbau vor Sicherheitsventil?

conditionally possible

Individual solutions

Your contact for Flat Metal Rupture Disc

Answering your questions precisely and competently - that is our goal.

Simply get in touch directly with your contacts from the divisions.